Advantages:

1) Compact volume, Diversified exterior

2) High precision of repeated location

3) Good performance of anti-interference

4) High on-off frequency, Wide voltage range

5) Dust proof, vibration proof, water proof and oil proof

6) With short-circuit protection and inverted connecting protection

Specification:

|

Dimension

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flush

|

Detection distance

|

2mm

|

|

|

|

NPN

|

NO

|

LJG5C-2/Z2CN1 / LMF22-3002NA

|

|

|

DC

|

NC

|

LJG5C-2/Z2DN1 / LMF22-3002NB

|

|

|

6

|

NO+NC

|

LJG5C-2/Z2EN1 / LMF22-3002NC

|

|

|

~

|

PNP

|

NO

|

LJG5C-2/Z2CP1 / LMF22-3002PA

|

|

|

36

|

NC

|

LJG5C-2/Z2DP1 / LMF22-3002PB

|

|

|

V

|

NO+NC

|

LJG5C-2/Z2EP1 / LMF22-3002PC

|

|

|

|

two wire system

|

NO

|

LJG5C-2/Z0AN1 / LMF22-3002LA

|

|

|

|

NC

|

LJG5C-2/Z0BN1 / LMF22-3002LB

|

|

|

AC

|

SRC Control label silicon

|

NO

|

LJG5C-2/J2AN1 / LMF22-2002A

|

|

|

90

|

NC

|

LJG5C-2/J2BN1 / LMF22-2002B

|

|

|

~250

|

NO+NC

|

|

|

|

V

|

Relay output

|

|

|

|

Non-flush

|

Detection distance

|

4mm

|

|

|

|

NPN

|

NO

|

LMF22-3004NA

|

|

|

|

NC

|

LMF22-3004NB

|

|

|

DC

|

NO+NC

|

|

|

|

6

|

PNP

|

NO

|

LMF22-3004PA

|

|

|

~

|

NC

|

LMF22-3004PB

|

|

|

36

|

NO+NC

|

|

|

|

V

|

two wire system

|

NO

|

LMF22-3004LA

|

|

|

|

NC

|

LMF22-3004LB

|

|

|

AC

|

SRC Control label silicon

|

NO

|

LMF22-2004A

|

|

|

90

|

NC

|

LMF22-2004B

|

|

|

~250

|

NO+NC

|

|

|

|

V

|

Relay output

|

|

|

|

Control output

|

DC

|

200mA

|

|

|

SCR/Relay

|

300mA

|

|

|

Output voltage dropDC/AC

|

DC<3V , DC(Two wire system)<3.9V , AC<10V

|

|

|

Consumption current

|

DC < 15mA, AC < 10mA

|

|

|

Standard detected object

|

15×15×1(A3 iron)

|

|

|

Repeated precision

|

0.01

|

|

|

DC/AC Response frequency

|

300Hz

|

|

|

Working environment temperature

|

–25℃~70℃

|

|

|

Insulation resistance

|

≥50MΩ

|

|

|

Shell material

|

ABS Resin

|

|

|

Protection grade

|

IEC standard IP67

|

|

|

Altemative model at home and abroad

|

|

|

Series connection and parallel connection:

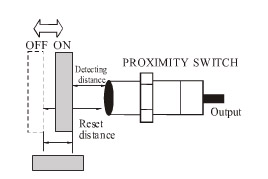

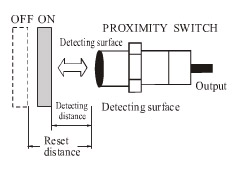

Explanation of technical terms:

|

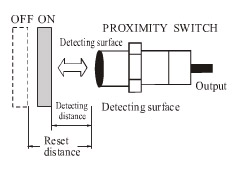

Detection distance

Move the detected object according to assigned method, the distance from the reference position (reference plane)to the detecting action(resetting)

|

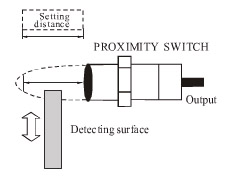

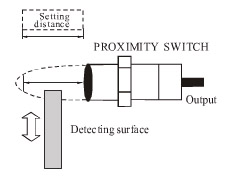

Setting distance

Including the effects like temperature and voltage, without error action the distance passed through from the practical detection surface to the objected object.

|

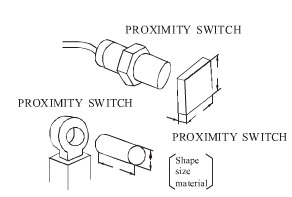

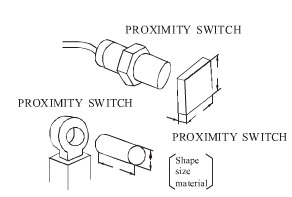

Standard detected object

Take as standard detected object to detect the basic performance. the shape, size and material have been determined.

|

|

Differential distance

The absolute value of the distance difference between the distance to action and the distance To resetting

|

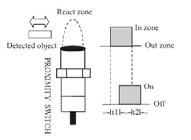

Response time

TI:when the objected object enters the action zone, the time from proximity sensor being in action state to output appearance.

T2:the time from leaving action zone to output disappearance.

|

Response frequency

Work out the tracking output times per second by repeatedly approaching the detected object

Brief detection method sees the above diagram

|

Main features:

Take high frequency oscillation type proximity sensor(front detector)as representative example to briefly explain general features of proximity switch.

|

Item

|

Explanation

|

Features

|

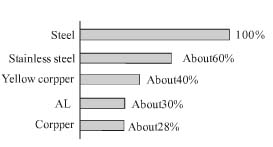

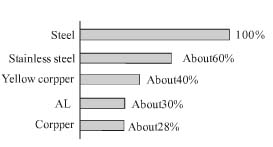

◆ About detected object

When the material of detected object is non magnetic metal, the distance of action should descend. But when the foil material is approximately thicker than a.01mm,the detection distance will be the same as that of magnetic object If the film plating is extremely thin or non-conductive, detection cannot be conducted. The effect of cladding material, take note of the changing of detection distance.

◆ About ambient weather

In order to maintain reliable action and long service life, please avoid the(outdoor)occasion beyond the stipulated ambient temperature. Do not drench it with Water or water-soluble cutting lubricant when it is used with cover, although the proximity sensor is waterproof. Do not used in the occasions with chemical agents, especially strong base acid, nitric acid, hot strong sulfuric acid and so on.

◆ About maintenance and overhaul

In order to keep the proximity sensor to work stably for long time, the following regular examinations should be performed just like general control.

1. Check the installation position of detected object and proximity sensor if any deviation, loosening or deformation exists.

2. Check the attached wires and connecting parts if any loosening bad contact or wire breaking off exists

3. Check if there is any metallic powder accumulation or not

4. Check if the temperature condition and surrounding environment condition are normal or not

5. Check if the detection distance is normal or not

|

|

The size of detected object and detection distance

|

If the detected object is square metal sheet with constant thickness (t=1mm), detect at detection distance X when change its side length dmm.

X(mm)

|

When the detected object is bigger than standard detection distance is constant. According to different Machine type, sometimes the features will that mentioned on the left. To through type, the detection object is like cylinder metal bar

|

|

The thickness of detected object and detection distance

|

Detect at detection distance Xmm(front detector)when change the thickness of the assigned standard detected object 1mm.

|

For more than 1mm thick magnetic metal like iron on the main, the detection distance will not change.

|

|

The effects resulted from the Thickness of detected object and cladding material

|

Because the detection to standard detected object will be effected by its shape, size, material, and various cladding material, confirm through detection distance Xmm measurement.

|

The effects resulted from detection distance and cladding material of the metal excluded iron will be different according to different machine type On the main, the machine type which detects all the metals will not be effected by cladding material.

|

Correct use, installation and cautions:

|

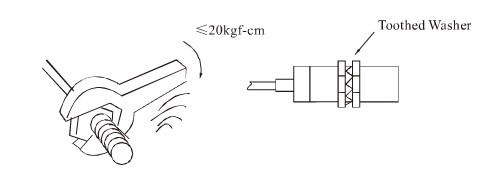

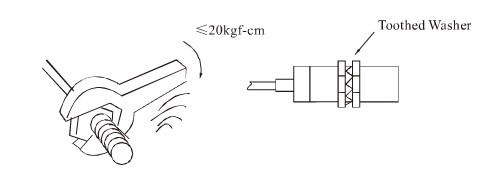

◆Mounting screw switch

◆ Do not tighten with over-torque when mounting the switch. Adopt toothed washer when tightening

|

◆ Mounting non screw type pillar switch

◆ When adopt adjusting screw, the tightening torque should be within 2-4kgf-cm

|

|

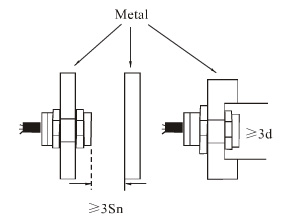

◆ Protection against the interference of non detected object

◆ When mounting the proximity switch on the metal part,

do refer to the following diagram. Remain a certain space in advance according to the shown diagram so as to prevent the switch from error action

|

◆ Protection against mutual interference between switches

◆ Mount according to the size which is bigger than that in the following diagram to prevent the switch from error action resulted from mutual interference if mount the switches contra-positively or in parallel

|

|

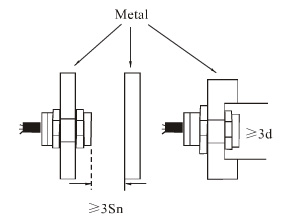

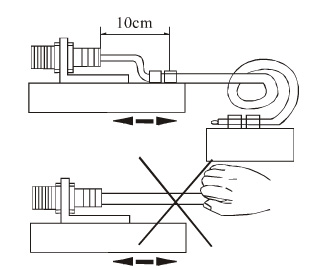

◆ Adjustable switch action distance(sensitivity)

◆ The action distance(sensitivity)of proximity switch can be adjusted by the means of trimming potentiometer. Increase the action distance and reduce sensitivity when turn clockwise. Vice versa. Do not use in the critical state of max. action distance.

|

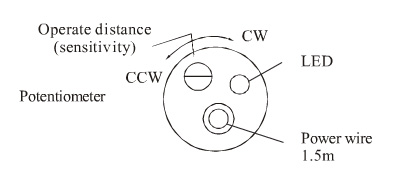

◆Guard of switch lead-wire

◆ When mount switch, fix the lead-wire at a distance about 10cm from the switch with wire clip so as to prevent the switch lead-wire from damage from outer force

|

■ Cautions

◆DC switch should adopt insulation transformer and ensure stable voltage mains corrugation.

◆IF any electric power line or dynamic line passes through the surrounding of switch lead-wire, in order to prevent the switch

from damage or error action, cover the metal bushing on the switch lead-wire and ground it to the earth.

◆Set the switch use distance within the rated distance to avoid the effects from temperature and voltage

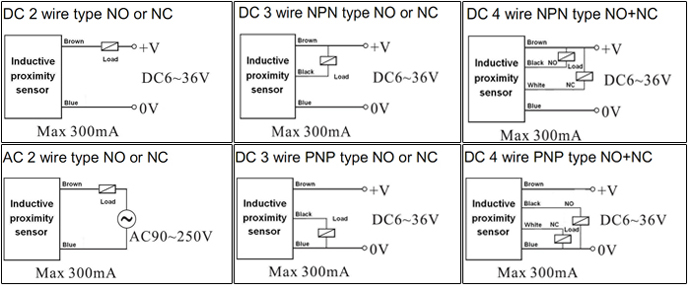

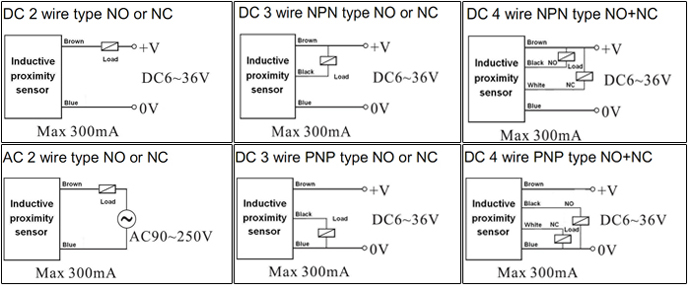

◆Wiring while power-on is strictly prohibited. Connecting the wires strictly according to the wiring diagram and output

return elementary diagram.

◆If there are any special requirements to the switch like water proof, oil proof, acid proof, base proof, high temperature proof

or with any other specifications, the users are required to give clear indication when placing an order. We can produce accord

-ing to the requirements of the use.

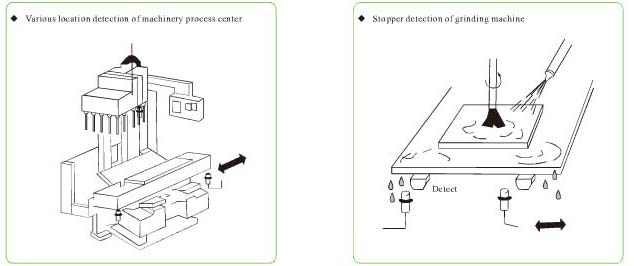

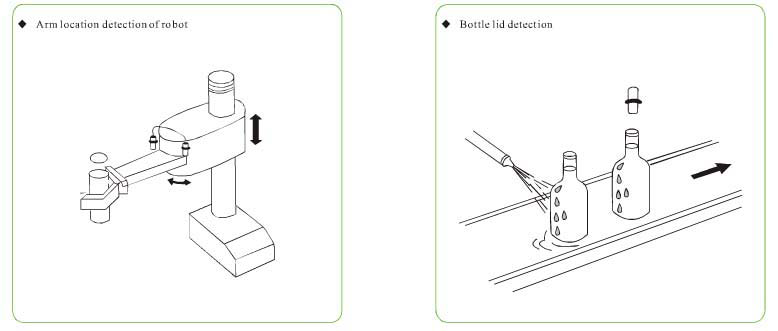

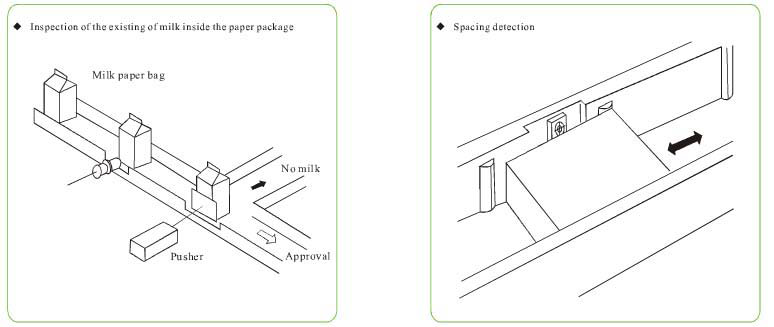

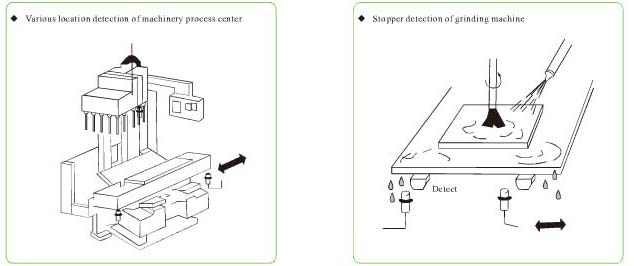

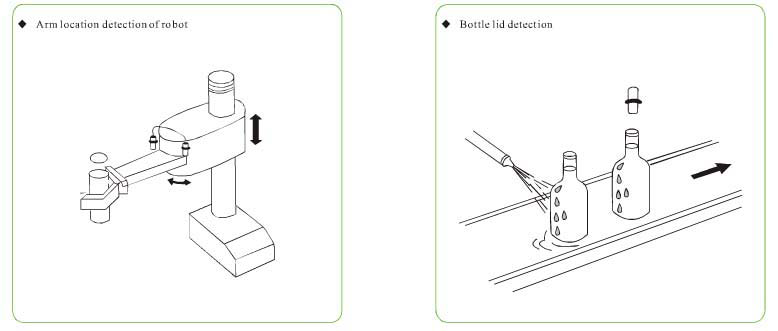

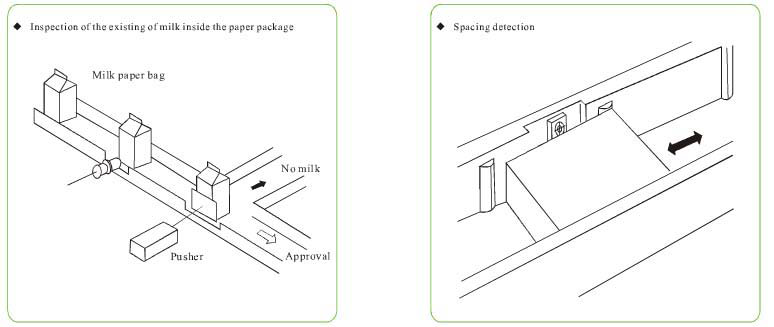

Application illustration of proximity switch:

|